1

Engineering Design Institute

12

Global Manufacturing Centers

20+

Years of Experience

1000+

Global Clients

CERTIFIED CLEANROOM PRODUCTS

Cleanroom Partition Panels

Modular, airtight panels ensuring contamination-free zones. Designed for fast installation, long-term durability, and compliance with ISO/GMP standards.

- Fire-resistant & anti-static options

- Seamless integration with doors and windows

- Quick assembly & modular flexibility

Cleanroom Doors

High-performance doors providing airtight integrity and minimal particle generation, suitable for controlled zones in pharmaceutical and biotech industries.

- Automatic and manual operation

- Seamless integration with partition panels

- Durable, easy-to-clean surfaces

Return Air System

Designed to maintain stable pressure differentials and controlled airflow circulation within cleanroom environments. Integrated seamlessly into wall or lower-panel structures to support HVAC balance and GMP-compliant airflow.

- Supports cleanroom pressure cascade and airflow balance

- Flush-mounted design for easy cleaning and no dust traps

- Optimized for HVAC coordination and maintenance access

Air Purification Equipment

HEPA/ULPA filtration systems for cleanrooms, ensuring high-efficiency particle removal and stable airflow control to maintain ISO-class environments.

- ISO-class compliant filtration

- Energy-efficient, low-noise design

- Smart monitoring for maintenance alerts

Cleanroom Furniture

GMP-compliant stainless steel furniture systems designed for cleanroom production, laboratories, and support areas. Built to withstand intensive cleaning, chemical exposure, and high-load operations.

- 304 stainless steel with rounded, weld-free edges

- Customizable tables, cabinets, racks, and sinks

- Designed to eliminate dead corners and simplify cleaning

Pass-Through Chamber

Enables safe transfer of materials between cleanrooms of different classifications while preventing cross-contamination.

- Air-tight and contamination-free design

- Optional interlock or UV sterilization

- Durable stainless-steel construction

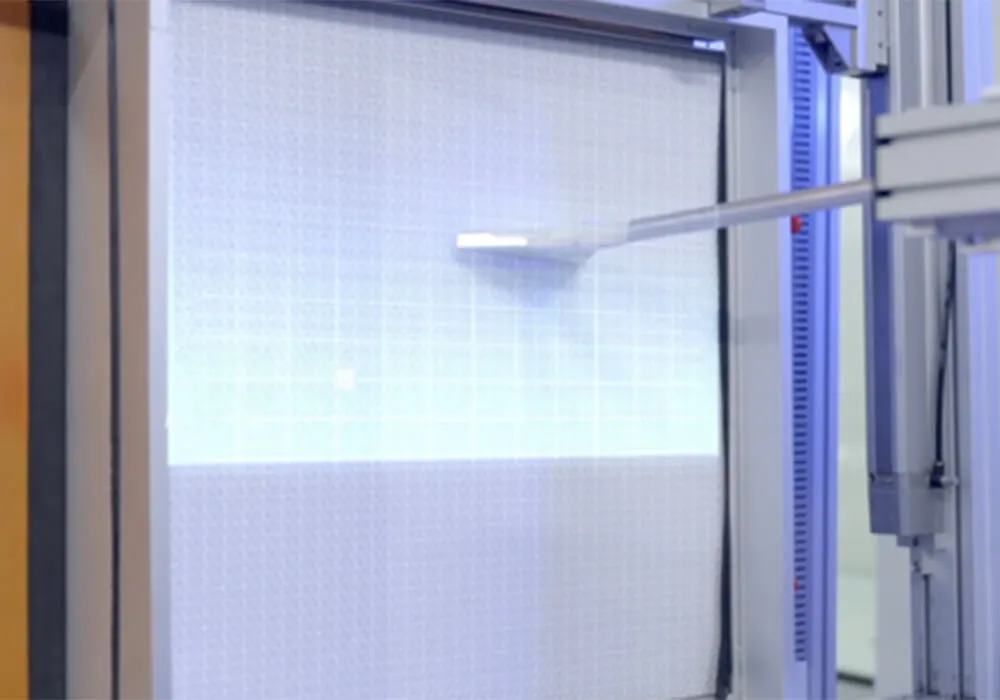

Laminar Airflow Unit

Provides unidirectional, HEPA-filtered airflow to maintain sterile conditions for sensitive processes in labs, production areas, and cleanrooms.

- ISO-class compliant laminar airflow

- Protects both product and operator

- Customizable size for various workstations

VHP Sterilization Transfer Chamber

Using VHP technology to safely decontaminate materials between clean areas. Designed for aseptic pharmaceutical and biotech applications requiring validated sterile performance.

- Achieves 6-log sporicidal reduction with uniform VHP distribution

- Automated decontamination, dwell, and aeration cycles

- Meets GMP and aseptic processing requirements

Cleanroom Envelope material system

Integrated wall & ceiling panels (PU / Rockwool / MgO), ceiling grid systems, return air grilles & exhaust outlets and door assemblies that deliver a sealed, easy-to-clean, and GMP-compliant room envelope.

purification & air Control equipment

FFU(Fan Filter Units), Interlocks, air-showers and pass-throughs designed to eliminate cross-contamination and protect process integrity.

Process Area Equipment

Localized purification and containment equipment for weighing, sampling and aseptic operations that protect product and operator.

Clean Utilities & Water Systems

Validated PW/WFI, pure steam and utility distribution systems engineered for pharmaceutical-grade reliability.

Cleanroom Product Ecosystem

We deliver end-to-end cleanroom ecosystems — from structural envelope to process utilities — designed for long-term compliance, maintainability and low total cost of ownership. Our integrated solutions meet the strictest industry standards for pharmaceutical, biotech, and medical device manufacturing.

Explore CertificatesTURNKEY

CLEANROOM

SOLUTIONS

From concept to completion, fully integrated EPC execution covering design, manufacturing, construction, validation, and long-term technical support — delivered under one accountable framework.

ABOUT US

Line-Link is a trusted provider of GMP-compliant cleanroom engineering with over 20 years of industry expertise and 12 manufacturing bases worldwide. We specialize in delivering high-end turnkey cleanroom solutions that meet the most rigorous GMP, FDA, and WHO standards, with cleanliness levels ranging from Class 100 to 100,000 (ISO 4–8, Class A–D). Our solutions serve diverse sectors including pharmaceuticals, biotechnology, semiconductors, healthcare, cosmetics, and food processing.

Our in-house manufacturing covers all critical cleanroom components—cleanroom panels, HEPA filters, purification equipment (including laminar flow units, air showers, etc.) and laboratory furniture—seamlessly integrated into complete cleanroom systems for fast delivery, consistent quality, and cost efficiency.

NEWS

Request Technical Consultation?

Engage with our engineering team to receive a structured feasibility review, technical recommendations, and a tailored quotation aligned with your process requirements and compliance standards.