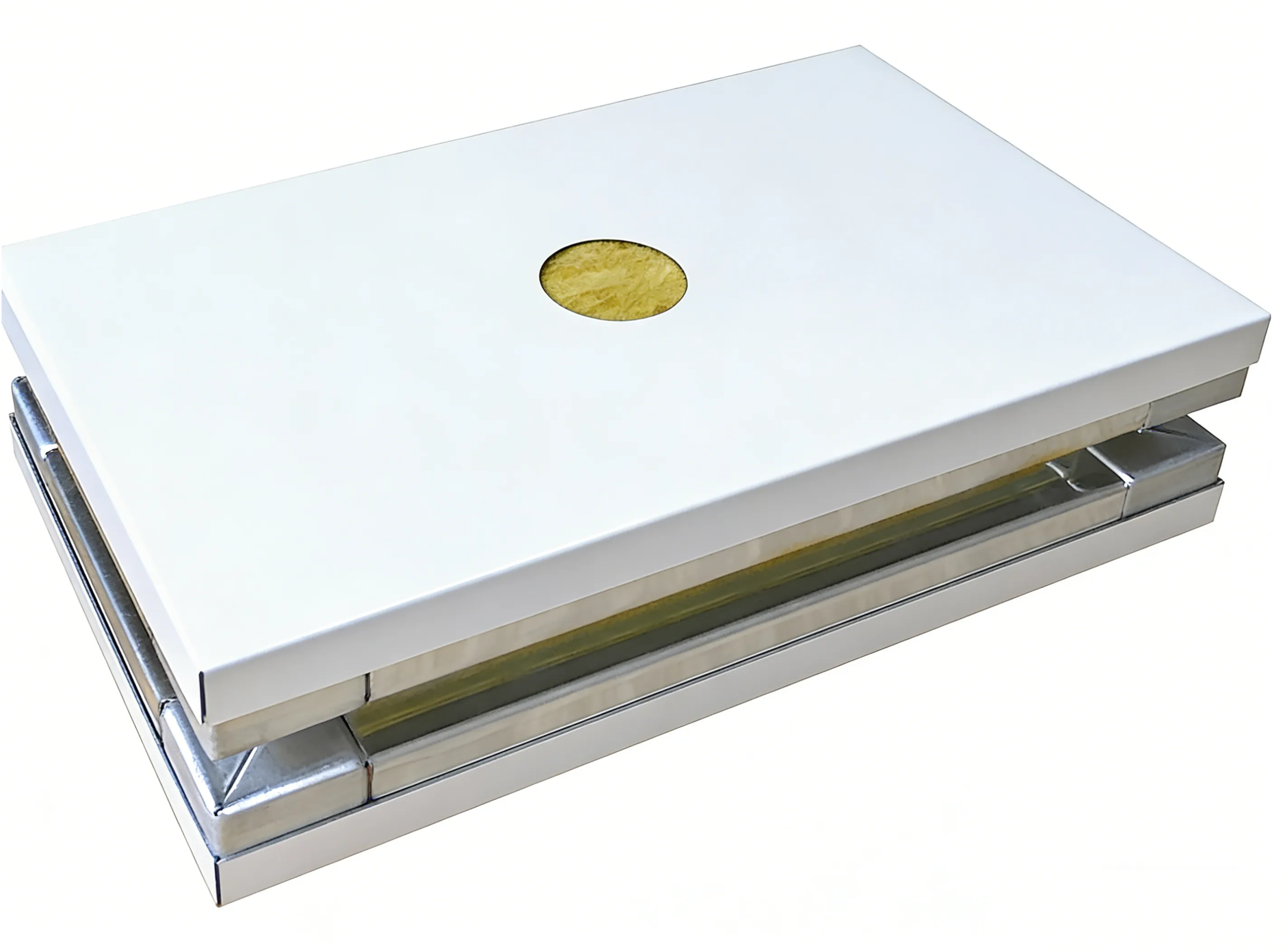

Fire Safety Priority

Fire Safety Priority

Rockwool Cleanroom Wall Panel

- A1 non-combustible fireproof

- H₂O₂ resistant

- High strength & stable structure

Solves: Fire code overrides all other considerations

High Cleanliness & Fire Rated

High Cleanliness & Fire Rated

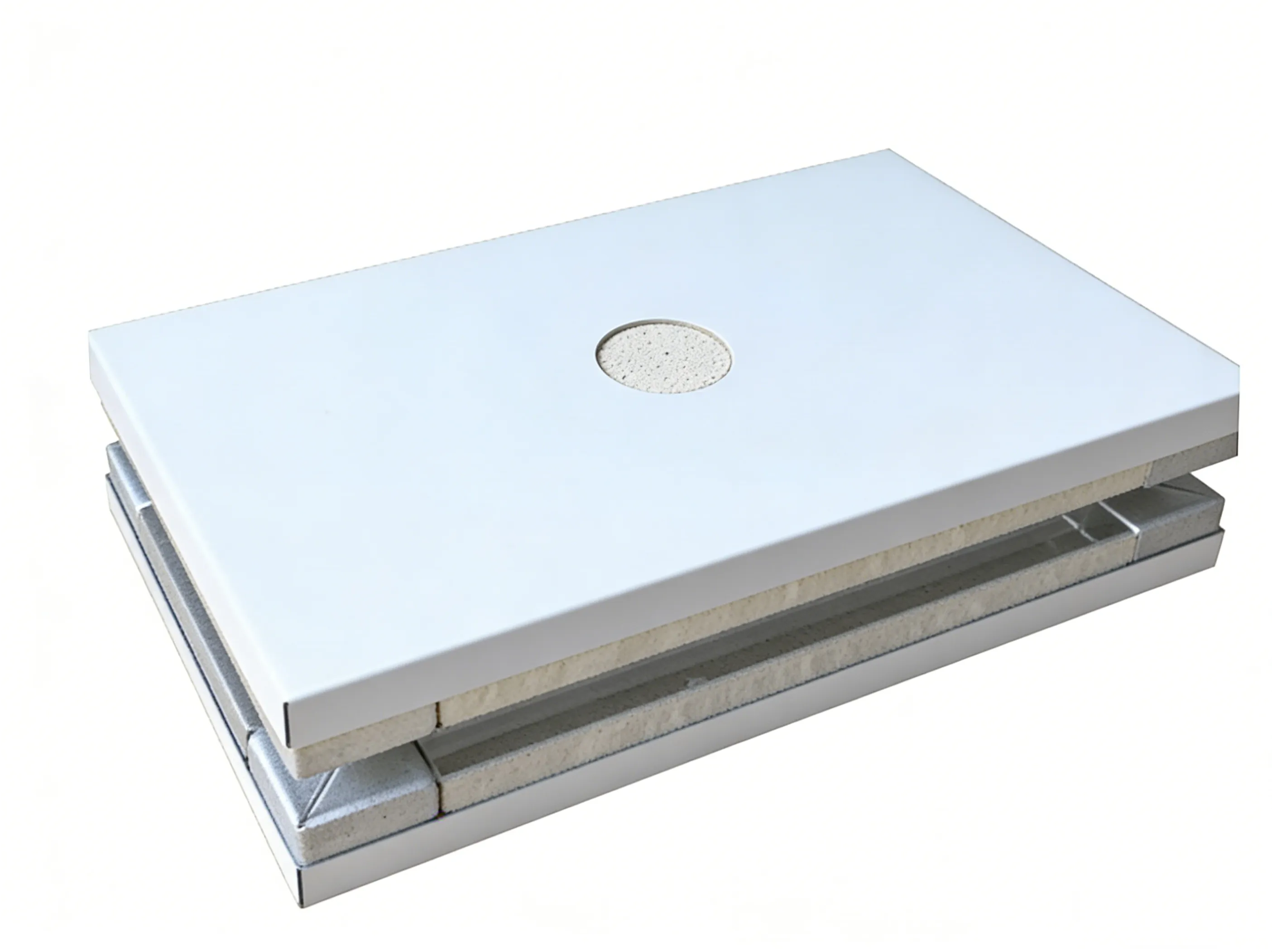

Magnesium Cleanroom Wall Panel

- No fiber shedding

- B-s1,d0 fire performance

- High rigidity

Solves: Non-combustible fire safety, cleanliness and solid structural strength are all required

Thermal Insulation

Thermal Insulation

PU/EPS/PIR Cleanroom Wall Panel

- Superior Thermal Insulation

- Lightweight & easy installation

- Energy-efficiency

Solves: Economic advantages than rockwool and magnesium systems

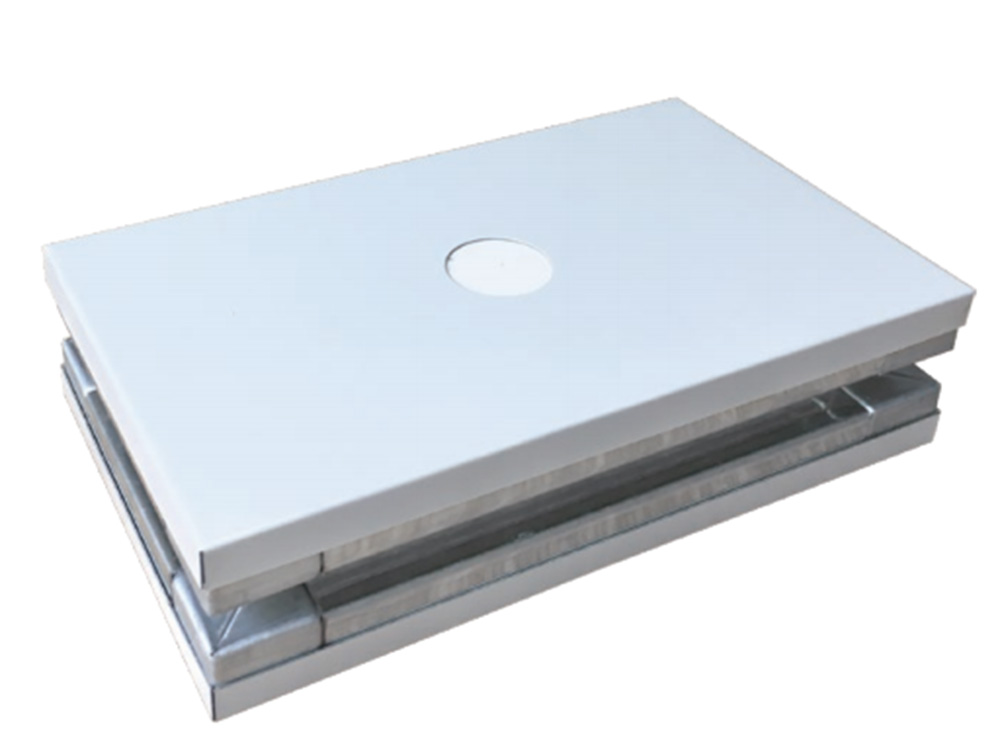

Lightweight Rigidity

Lightweight Rigidity

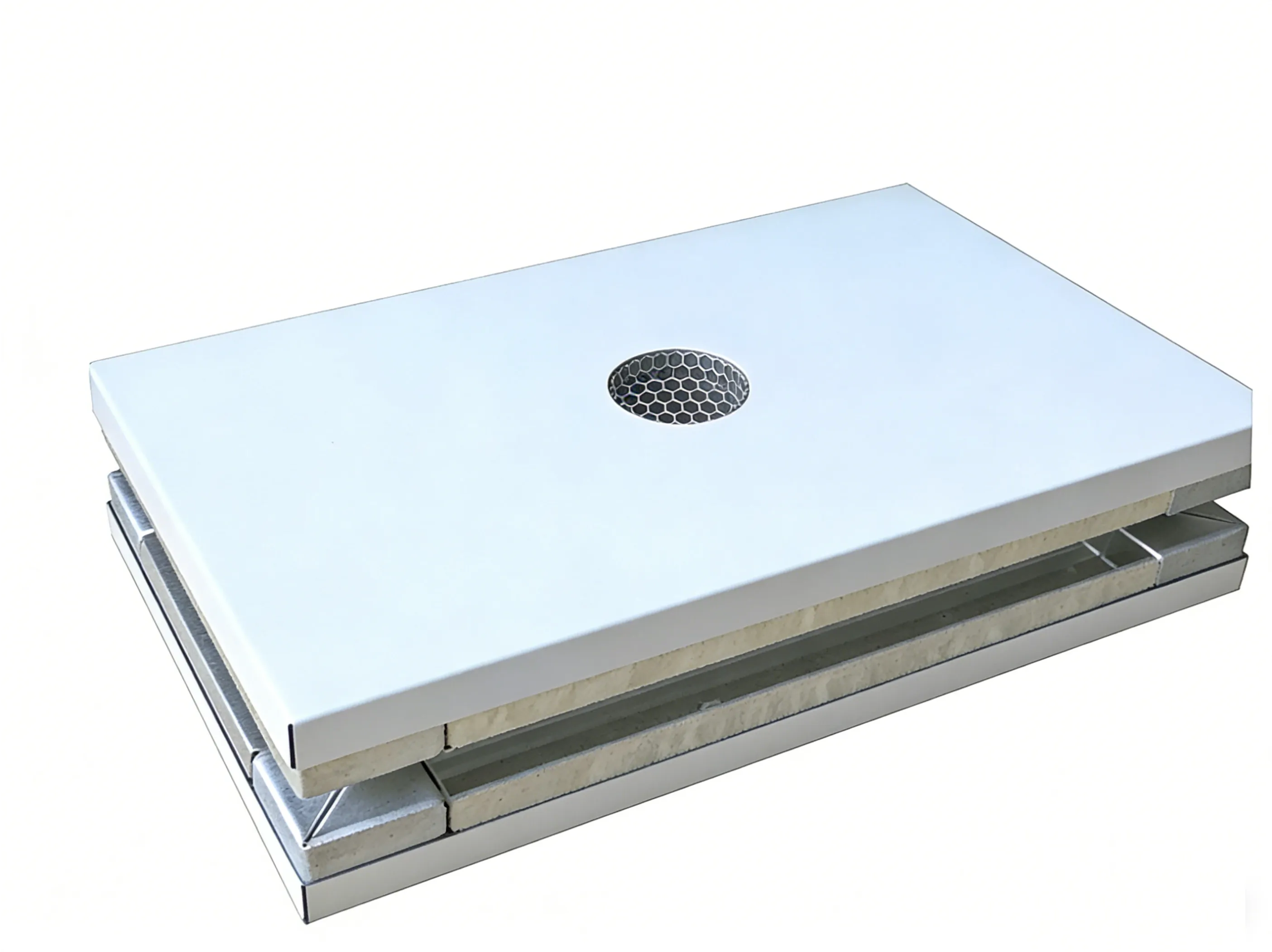

Aluminum/Paper Honeycomb Panel

- Lightweight core & Modularity

- Smooth surface

- Low particle accumulation

Solves: Structural load limits and fast installation

Hygiene & Durability

Hygiene & Durability

HPL/Stainless-steel Wall Panel

- VHP Chemical resistance

- Certified Anti-scratch

- long service life

Solves: Maintenance concerns and surface-lifecycle decision

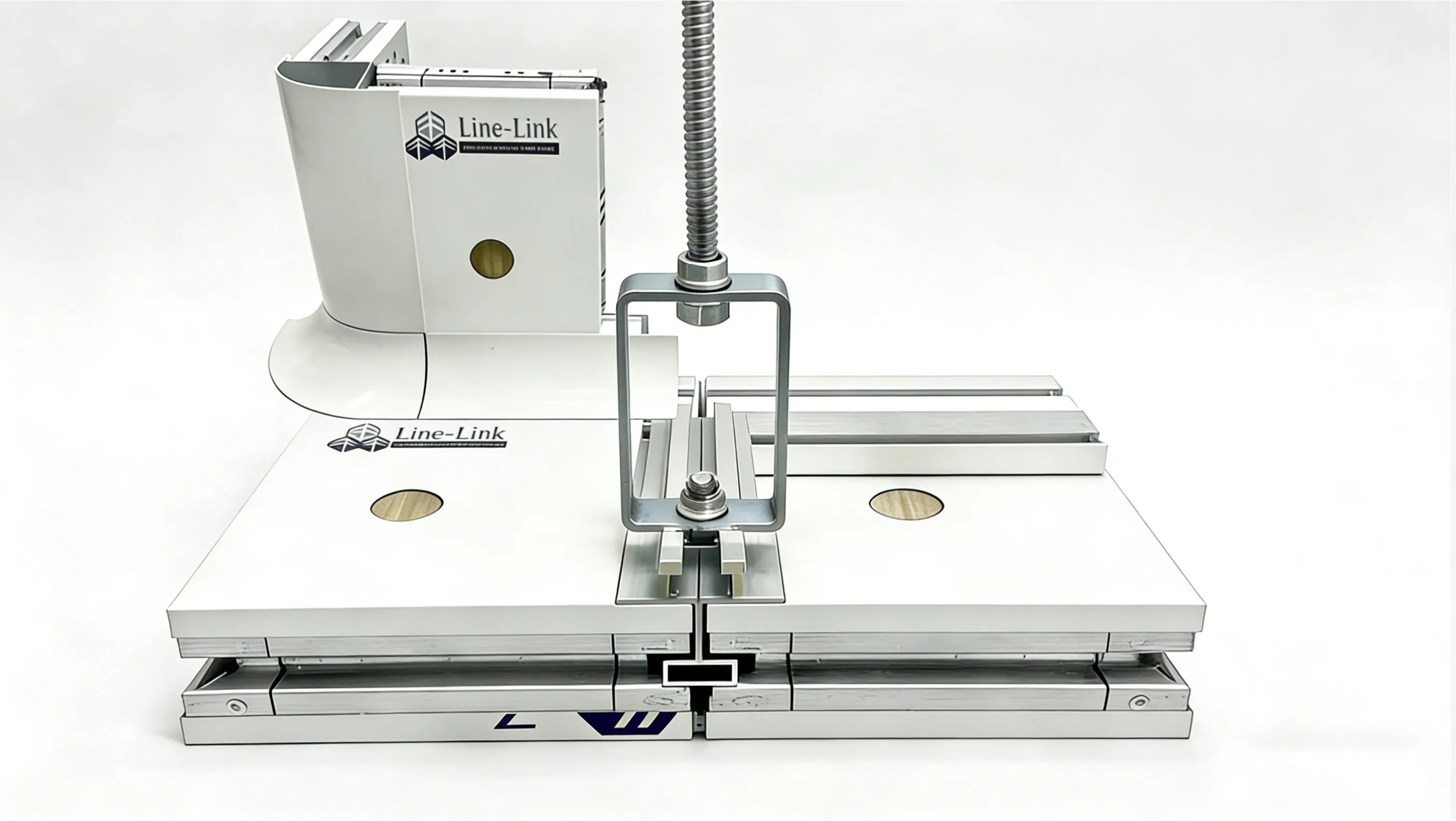

Precision Manufacturing

Precision Manufacturing

Machine-made Sandwich Panel

- ±0.1mm accuracy

- Continuous production

- Uniform density

Solves: Inconsistent quality

High Load & Airtight

High Load & Airtight

Ceiling Panels

- High load stability

- Airtight joint design

- Rapid reconfiguration

Solves: Structural sagging in large cleanrooms & High cost of future renovations

Airflow Control

Airflow Control

100mm Return Air Grille Panel

- Adjustable & stable air volume

- Integrated panel structure

- Pressure balance

Solves: Uneven air distribution

Flexible & Modular

Flexible & Modular

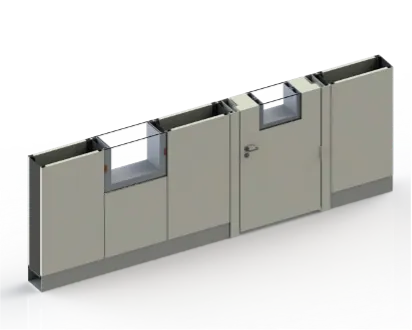

Detachable Hollow Wall Panel

- Detachable modular design

- Hollow core structure while maintaining a clean, flat wall surface

- Cleanroom-sealed ensuring consistent cleanliness

Solves: Enables flexible cleanroom modifications and hidden service routing without breaking walls or disrupting operations

Pressure Integrity

Pressure Integrity

Airtight Cleanroom Door

- Engineered leakage control, not nominal “airtight” claims

- Adjustable sealing to compensate wall and frame tolerances

- Proven pressure stability under frequent door cycling

Solves: Pressure leakage and cross-zone contamination in critical environments

Traffic Control

Traffic Control

Automatic Sliding Door

- Touch-free operation designed for real GMP workflows

- Stable motion under continuous, high-cycle use

- Sliding system tuned to avoid airflow disturbance

Solves: Space constraints in compact cleanroom layouts

Fire–GMP Balance

Fire–GMP Balance

Cleanroom Steel Door

- Fire rating achieved without breaking cleanroom sealing logic

- Integrated smoke control compatible with pressure zoning

- Designed for cleanroom corridors, not generic fire doors

Solves: Fire safety compliance without compromising cleanroom integrity

Hygiene Control

Hygiene Control

Stainless Steel Cleanroom Door

- Full stainless surface to withstand aggressive cleaning

- Non-porous construction to eliminate microbial retention

- Long-term corrosion resistance in wet or chemical environments

Solves: Material degradation and hygiene failure under intensive GMP cleaning

Life Safety

Life Safety

Emergency Door

- Allows fast exit while maintaining pressure control logic

- Fail-safe opening under power loss or emergency conditions

- Designed to evacuate without compromising enclosure integrity

Solves: Safe evacuation without destroying cleanroom pressure and layout logic

High Efficiency

High Efficiency

HEPA Filters

- 99.97% efficiency at 0.3μm

- Low pressure drop

- Long service life

Solves: Maintaining ISO Class 4-8 cleanroom environments

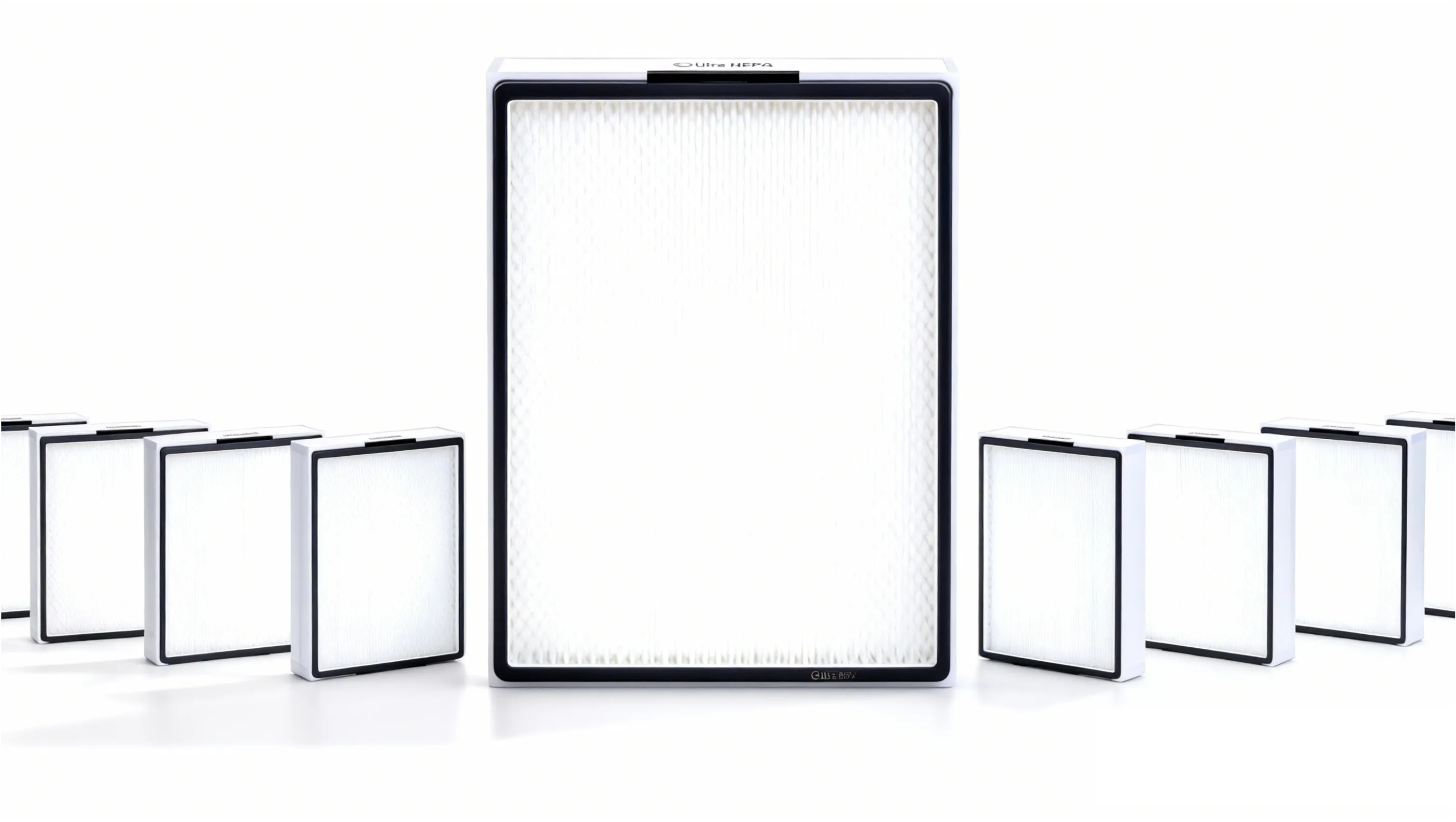

Ultra High Efficiency

Ultra High Efficiency

ULPA Filters

- 99.9995% efficiency at 0.12μm

- ISO Class 1-4 compliance

- Minimal particle shedding

Solves: Critical applications requiring ultra-low particle counts

Modular Air Supply

Modular Air Supply

Fan Filter Units (FFU)

- Ready-to-use installation

- Variable speed control

- Energy efficient DC motors

Solves: Flexible cleanroom ceiling layouts and retrofits

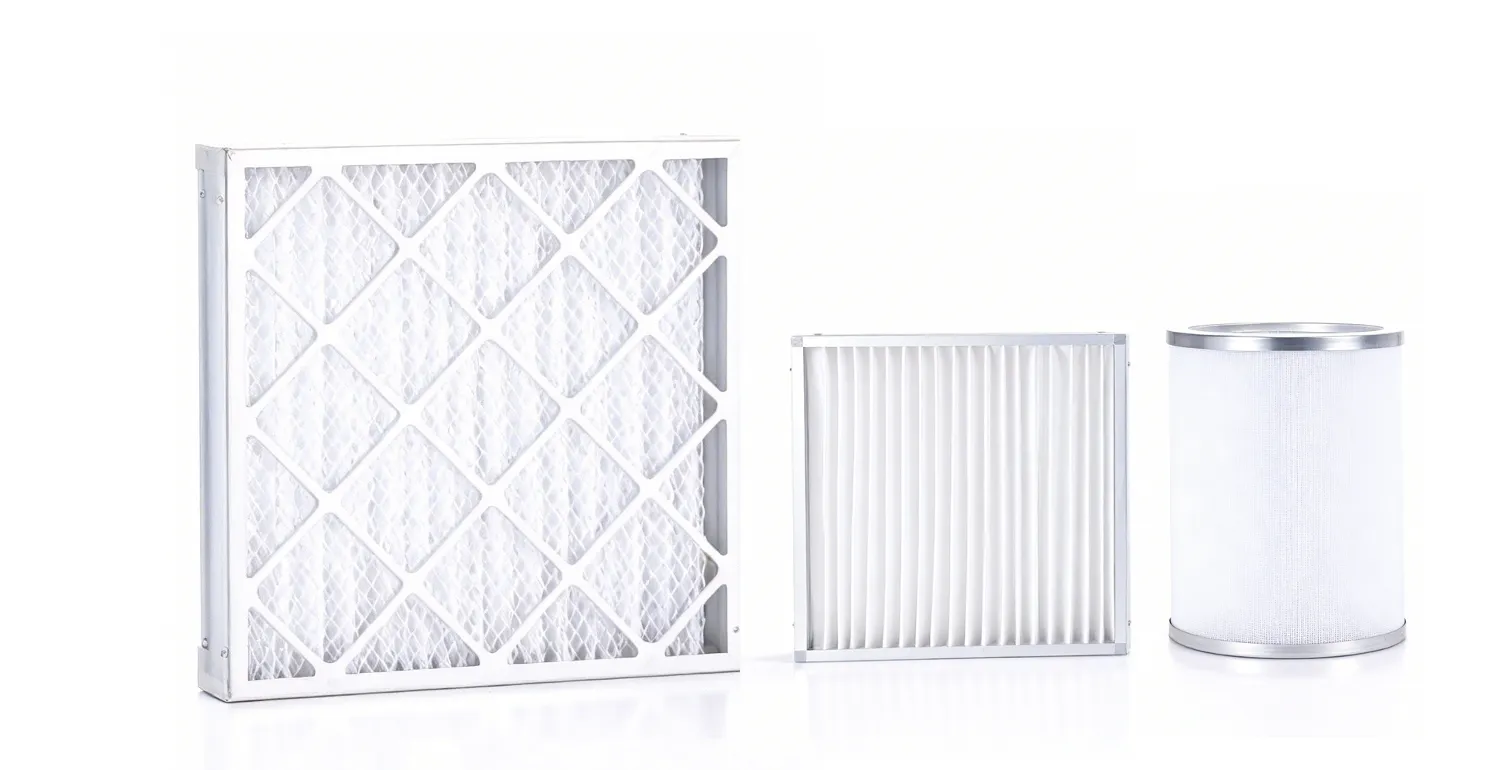

Fast Start

Fast Start

Primary Filter

- Quick installation

- Variable speed control adapt to changing process demands without redesign

- Energy efficient and saving operating costs from day one

Solves: Flexible cleanroom ceiling layouts and retrofits and the 1st protection

Easy Upgrade

Easy Upgrade

Medium Filter

- Drop-in replacement avoiding downtime and retrofit headaches

- Adjustable speeds for zone control

- Energy-efficient operation reducing ongoing utility expenses

Solves: Flexible cleanroom ceiling layouts and retrofits

Max Performance

Max Performance

W-type Filter

- Highest filtration with simple install

- Real-time airflow matching dynamically adjusting to process peaks and troughs

- Premium efficiency without high cost

Solves: Superior contamination control in compact layouts

Heat Ready

Heat Ready

High Temperature Filter

- Ensures reliable operation in high-heat environments with plug-and-play stability.

- Maintains precise airflow control despite thermal fluctuations, protecting process integrity.

- Prevents motor strain and energy waste under continuous thermal loads.

Solves: Dependable cleanroom performance and retrofits where temperature is a critical factor

Pure Air

Pure Air

HEPA Box

- Delivers absolute filtration integrity with zero-install-risk, plug-and-play setup.

- Adjusts airflow dynamically to meet stringent, real-time purity requirements.

- Sustains high-efficiency filtration continuously without energy penalty.

Solves: Achieving and maintaining highest air purity standards in adaptable ceiling layouts.

Differential Pressure During Transfer

Differential Pressure During Transfer

Cleanroom Pass Boxes

- Maintains critical differential pressure between zones

- Mechanical or electrical interlock system prevents cross-contamination

- Stainless steel construction with smooth, cleanable surfaces

Solves: Safe transfer of materials between different cleanliness zones

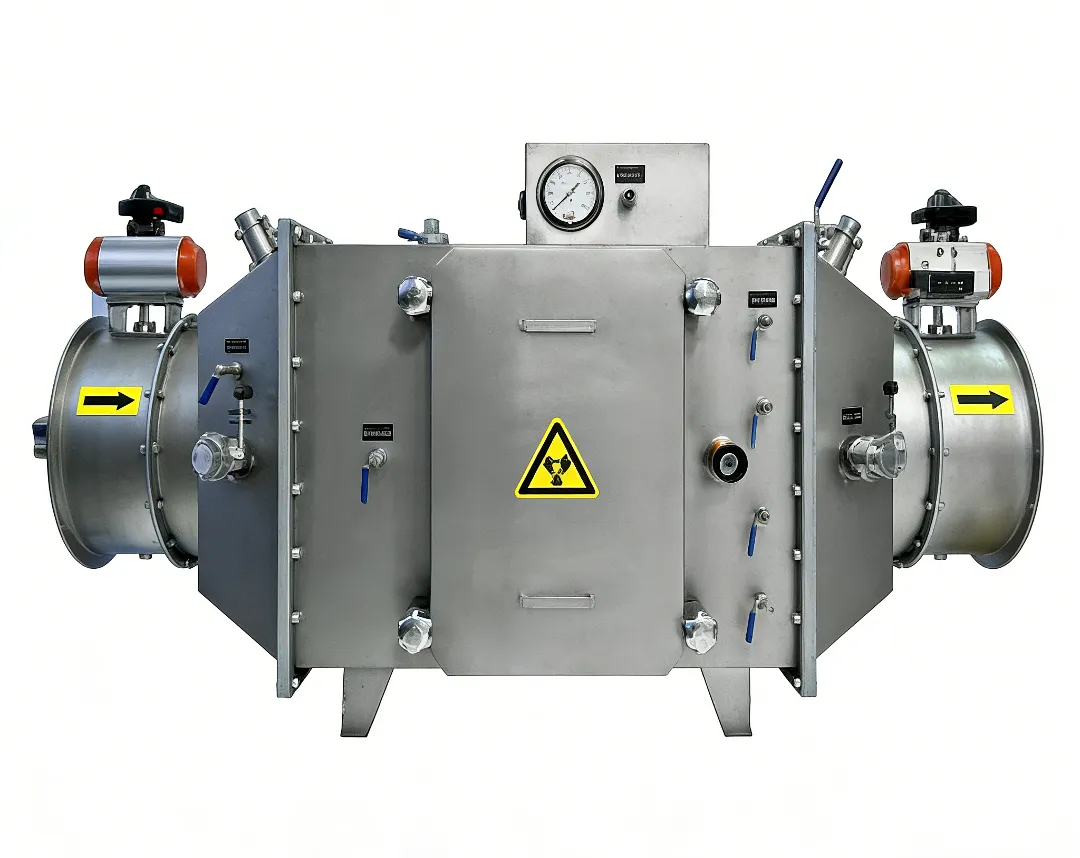

Zero Leakage

Zero Leakage

Biosecurity Airtight Pass Box

- Guarantees absolute containment for hazardous materials

- Sealed gaskets & pressure-rated construction for full containment

- Double-door airtight interlocks with pressure decay test ports

Solves: Safe transfer of materials between different cleanliness zones

Cycle Validated

Cycle Validated

VHP Pass Boxes

- Integrated VHP generator & catalyst

- Validated decontamination cycles with automated logging

- Compatible construction (316L SS, sealed welds) for aggressive sterilization

Solves: High-level surface decontamination of materials entering sterile cores or isolators, reducing transfer time.

Comprehensive Sterilization

Comprehensive Sterilization

VHP Sterile Transfer Pass Box

- Multi-cycle VHP generator for adjustable sterilization of tools, components, and packaging

- Validated biological indicator (BI) kill for a 6-log reduction, providing documented evidence

- UV Sterilization

Solves: Provides validated, high-level sterilization gateway for a wide range of non-thermal tolerant materials entering aseptic areas

Particulate Scrubbing

Particulate Scrubbing

Air Showers

- High-velocity, ISO 5 HEPA-filtered air nozzles (20-25 m/s) for effective particle dislodgment

- Programmable, sensor-activated cycle with adjustable duration and interlocks with cleanroom doors

- Stainless steel construction

Solves: Removes loose surface particulates from personnel garments before entry into critical zones

Surface Decontamination

Surface Decontamination

Mist Showers

- Fine mist or vaporized disinfectant dispersal system

- Closed-loop circulation and neutralization to ensure operator safety and prevent chemical ingress into clean areas

- Corrosion-resistant construction

Solves: Removing particles from personnel before entering clean zones

Mandatory Safety

Mandatory Safety

Compulsory Showers

- Safety-interlocked entry/exit doors ensure full cycle completion before release

- High-volume water deluge system with temperature control and pre-programmed wash/rinse cycles

- Chemical-resistant

Solves: Enforces mandatory personal decontamination for personnel exiting potent compound or high-containment areas, protecting the external environment and complying with strict health & safety protocols

Emergency Rinse

Emergency Rinse

Chemical Showers

- Instant-activation pull-handle or treadle system for hands-free, immediate operation

- Automatic timing control

- Corrosion-resistant construction

Solves: Provides immediate first-aid decontamination for accidental chemical exposure on personnel, minimizing injury severity and facilitating emergency response within labs or production areas

Localized Cleanliness

Localized Cleanliness

Laminar Flow Hoods

- Class 100 work area

- Uniform airflow velocity

- Low turbulence

Solves: Creating localized clean environments for sensitive processes

Flexible Protection

Flexible Protection

Mobile Laminar Flow Hoods

- Portable cart-mounted design with lockable casters for flexible repositioning in the facility

- Self-contained HEPA filtration unit with battery or plug-in operation for temporary ISO 5 coverage

- Lightweight & durable, providing a unidirectional airflow envelope

Solves: Provides temporary, movable particle-free workspace for batch-specific tasks, spot repairs without the cost and lead time of fixed installation

Contained Dispensing

Contained Dispensing

Sampling/ Weighing Booth

- Negative pressure containment with inward airflow to protect the operator from powder exposure

- Integrated precision balance shelf with anti-vibration mounting and easy-clean surfaces

- Smooth, CIP-capable interiors

Solves: Safely contains high-potency powders during sampling, weighing, and dispensing operations, minimizing cross-contamination and operator exposure to hazardous active pharmaceutical ingredients (APIs)

Product Protection

Product Protection

Clean Bench

- Vertical or horizontal laminar airflow (ISO 5) creating a particle-free zone over the work surface

- Ergonomic, open-front design for easy access while maintaining airflow integrity for product safety

- Durable, static-dissipative work surface suitable for non-hazardous material assembly or inspection

Solves: Protects sensitive products or processes from ambient particulate contamination during assembly, packaging, or inspection tasks where operator protection is not the primary requirement

Safe Filter Change

Safe Filter Change

BIBO

- Focuses on personnel safety during hazardous maintenance; Sealed containment housing with glove ports for handling contaminated filters without exposure

- Integral bag attachment frames and interlocking mechanisms to maintain containment during change-out

- Designed for toxic, pathogenic, or radioactive applications

Solves: Enables the safe removal and replacement of contaminated HEPA/ULPA filters in exhaust or intake systems, protecting maintenance personnel and the environment from hazardous particulates

Ergonomic Seating

Ergonomic Seating

Cleanroom Bench

- 304 or 316L stainless steel tops with electropolished finishes for chemical resistance

- Easy to clean surfaces

- Non-shedding

Solves: Provides stable, non-shedding seating for gowned personnel during extended tasks, minimizing fatigue and particle generation without contamination or static risks.

Process Work Surfaces

Process Work Surfaces

Cleanroom Workbenches

- 304 or 316L stainless steel tops with electropolished finishes for cleanability and chemical resistance

- Sturdy, vibration-resistant understructure for sensitive weighing or assembly

- ESD protection available

Solves: Delivers a rigid, easy-to-sanitize foundation for critical processes (e.g., assembly, inspection, packaging)

Material Storage

Material Storage

Cleanroom Storage Cabinets

- Smooth, cleanable surfaces

- Modular configuration

Solves: Preserves the cleanliness and organization of in-process materials, tools, and components

Vertical Process Flow

Vertical Process Flow

Cleanroom Rack

- Stainless steel construction

- Modular, bolt-free design

- Load-rated structure with leveling feet for stable storage

Solves: Maximizes vertical space for organized, accessible staging of components during batch production

Vertical Process Flow

Vertical Process Flow

Mobile Cleanroom Cart

- Stainless steel construction

- Modular, bolt-free design

Solves: Enables safe, contained transfer of tools, samples, or instruments between zones without compromising cleanliness

Hygienic Point-of-Use

Hygienic Point-of-Use

Cleanroom Wall-mounted Hand Washing Sink

- Stainless steel construction

- Hands-free, sensor-operated faucet

- Rough-in plumbing designed for cleanroom wall panels

Solves: Provides a compliant, easy-to-sanitize hand hygiene station directly within the gowning or process area

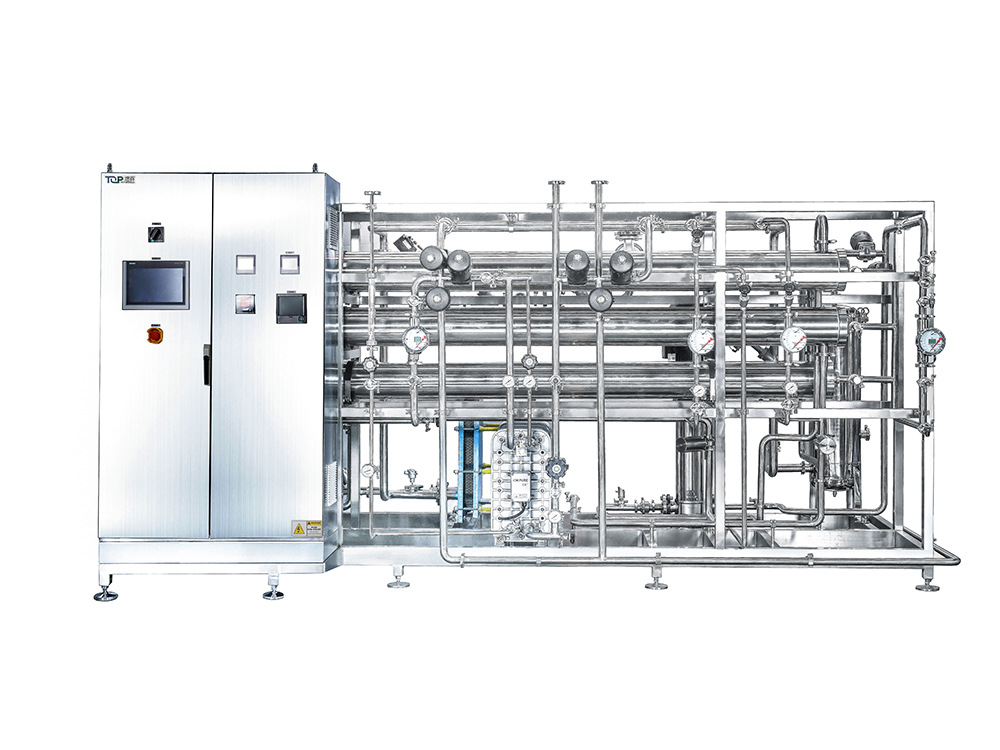

Validated Purification

Validated Purification

Purified Water Generator

- Multi-stage RO with controlled rejection performance for ionic and organic load reduction

- Optional EDI or polishing loop to stabilize conductivity without chemical dosing

- Design compliant with GMP documentation and validation expectations

Solves: Reliably produces USP Purified Water from pretreated feed water by removing ions, organics, and microorganisms, ensuring consistent quality for pharmaceutical production and laboratory use

Thermal Assurance & Polishing Treatment

Thermal Assurance & Polishing Treatment

Multi-effect Water Distiller

- Multi-effect, energy-efficient design using steam or mechanical vapor compression to produce pyrogen-free water

- Fully thermal process without resins or chemical regeneration

- Stable distillate quality meeting WFI requirements under continuous operation

Solves: Consistent WFI production

that meets USP endotoxin and sterility assurance requirements without relying on chemical sanitization, suitable for parenteral and sterile product manufacturing.

PW/WFI Microbial Control & Loop Integrity

PW/WFI Microbial Control & Loop Integrity

Storage & Distribution System

- Continuous circulation with defined velocity to prevent microbial growth in stagnant zones

- Dead-leg-controlled sanitary piping with orbital welding and drainability

- Online monitoring for temperature, conductivity, TOC, and system status

Solves: Maintaining produced water quality from generation through every point of use, day after day

Intrinsic Sterility

Intrinsic Sterility

Pure Steam Generator

- Pure steam generation from qualified PW or WFI with controlled phase separation

- All product-contact surfaces designed for condensate purity and endotoxin control

- Sanitary, self-draining design with minimal dead legs for consistent pure steam delivery to SIP points & distribution loops

Solves: Providing sterile, non-pyrogenic steam suitable for direct product contact and critical sterilization processes

Precise Batching

Precise Batching

Solution Preparation System

- Continuous turbulent flow loop with sanitary orbital-welded piping (316L SS) to prevent stagnant zones

- Precise control of concentration, temperature, and mixing time for batch repeatability

- Designed for CIP/SIP compatibility to meet pharmaceutical cleaning requirements

Solves: Ensuring consistent, contamination-controlled preparation of pharmaceutical solutions prior to filling or processing

Aseptic Processing & Integrity

Aseptic Processing & Integrity

Aseptic Filling Machines

- Integrated within RABS or isolator to maintain Grade A/ISO 5 conditions during vial or syringe filling

- High-repeatability dosing systems ensuring fill accuracy across multiple batch sizes

- Full CIP/SIP capability with documented cycle data for simplified validation and changeover

Solves: Enables the high-speed, aseptic filling of sterile liquids (vaccines, biologics, ophthalmics) without compromising sterility assurance, directly supporting compliance with Annex 1 and reducing product loss from contamination or fill variation.

Containment Certainty

Containment Certainty

Containment Isolators

- Closed system with negative pressure and HEPA filtration for handling defined OEB and exposure limits

- Gloveports with rapid transfer systems (RTPs) for safe material transfer without exposure

- Modular design with cleanroom integration for flexible use in dispensing, sampling, or lyophilization loading

Solves: Safe handling of potent or hazardous materials without compromising product quality or operator safety

Penetration Reliability

Penetration Reliability

Pulse Vacuum Sterilizer

- Pulse vacuum process enabling effective air removal from porous or complex loads

- Validated sterilization cycles aligned with pharmaceutical GMP requirements

- Chamber and load design supporting reproducible heat and steam penetration

Solves: Achieving reliable sterilization of instruments, materials, and components prior to aseptic use

Uniform Lethality & Chemical-Free Sterilization

Uniform Lethality & Chemical-Free Sterilization

Superheated Water Sterilizer

- Superheated water circulation ensuring uniform heat transfer across complex loads

- Precise temperature and pressure control suitable for sealed containers and devices

- Automated fill, heat, and drain sequences with full data logging for compliance

Solves: Reliable sterilization of heat-sensitive products and containers with reduced risk of cold spots or product damage

Seal Verification

Seal Verification

Glass Ampoule Auto Leak Test Machine

- Non-destructive leak detection tailored for sealed glass ampoules

- Automated handling system with 100% inline testing at production speed and automatic rejection of defective units

- Repeatable test conditions to support batch release and GMP documentation

Solves: Ensures the hermetic integrity of filled and sealed glass ampoules post-lyophilization, preventing sterility failure, moisture ingress, and product degradation throughout the shelf life

Inline Assurance

Inline Assurance

BFS Ampoule Auto Leak Test Machine

- Leak testing adapted to BFS container geometry and forming characteristics

- Automated inspection synchronized with BFS production output

- Detection sensitivity aligned with pharmaceutical container integrity requirements

Solves: Performs reliable, non-destructive leak detection on single-piece plastic ampoules to guarantee container integrity for parenteral products, ensuring patient safety and compliance with regulatory standards for sterile packaging.

Products

faq

-

What types of cleanroom wall panels are available, and how do they differ in performance and application?

-

How do I choose between fire-rated panels and insulation-focused panels?

-

Are all panels suitable for different cleanroom iso classes?

-

Are hollow or honeycomb panels suitable for concealing utilities?

-

What is the difference between handmade and machine-made partition panels?