Fire Safety Priority

Fire Safety Priority

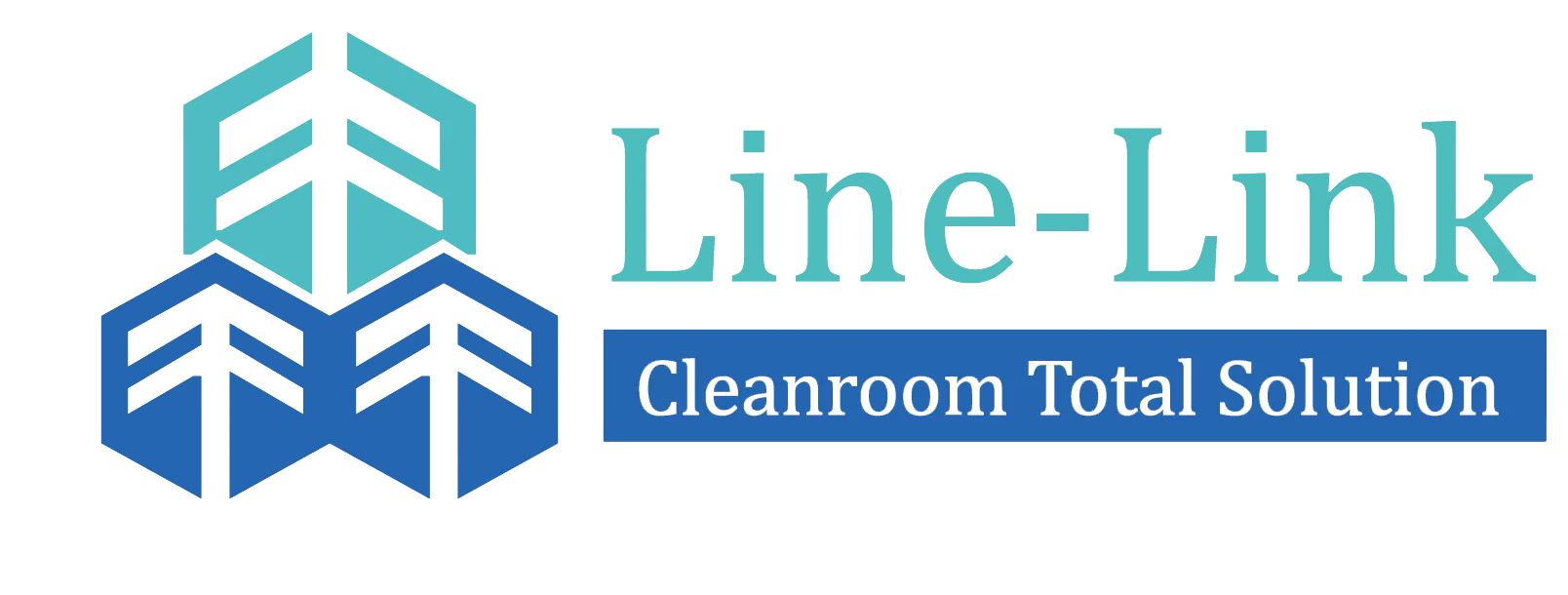

Fireproof Rockwool Cleanroom Panel

- A1 non-combustible fireproof

- H₂O₂ resistant

- High strength & stable structure

Solves: Fire code overrides all other considerations

High Cleanliness & Fire Rated

High Cleanliness & Fire Rated

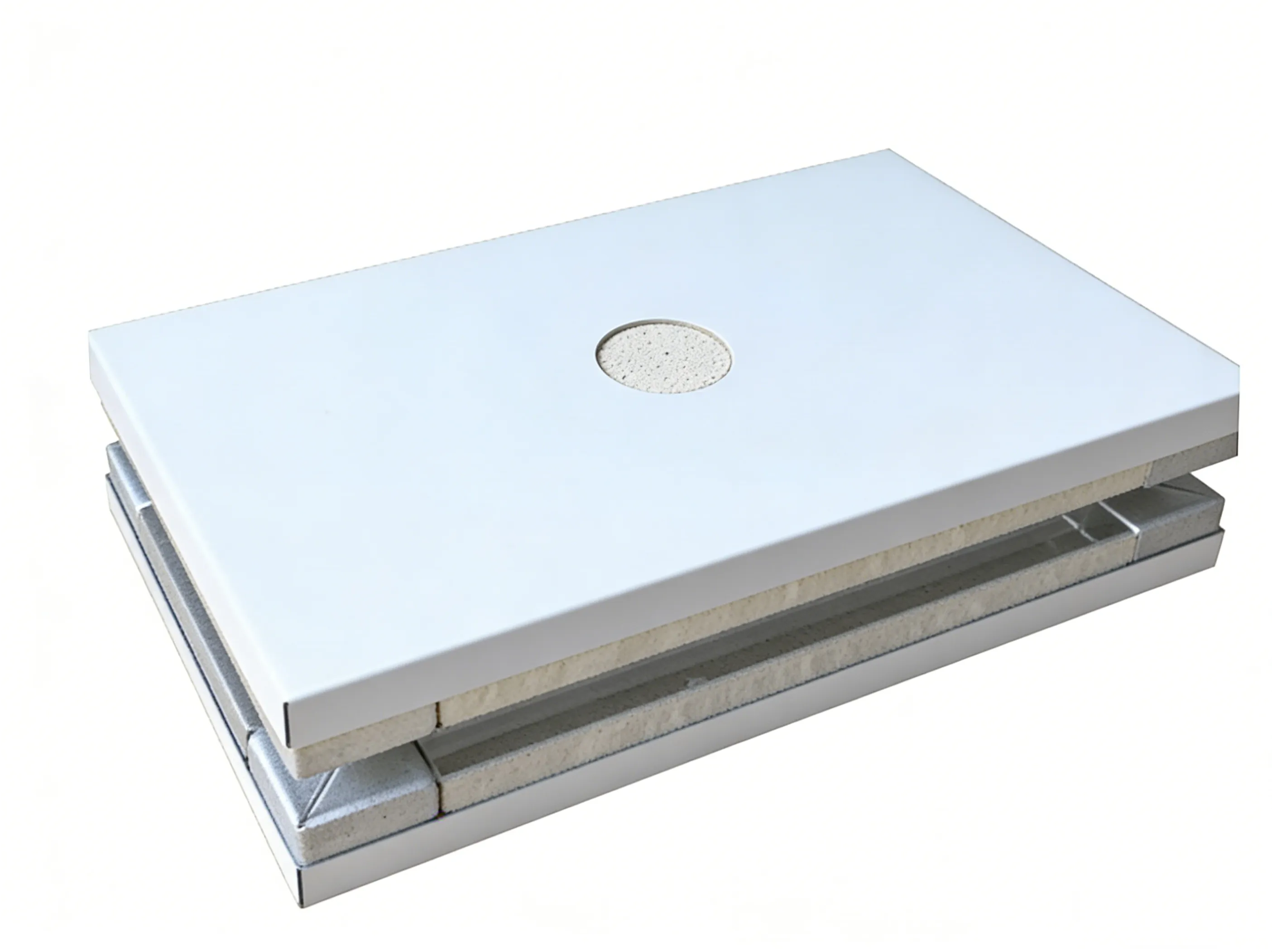

Magnesium Cleanroom Panel

- No fiber shedding

- B-s1,d0 fire performance

- High rigidity

Solves: Non-combustible fire safety, cleanliness and solid structural strength are all required

Thermal Insulation

Thermal Insulation

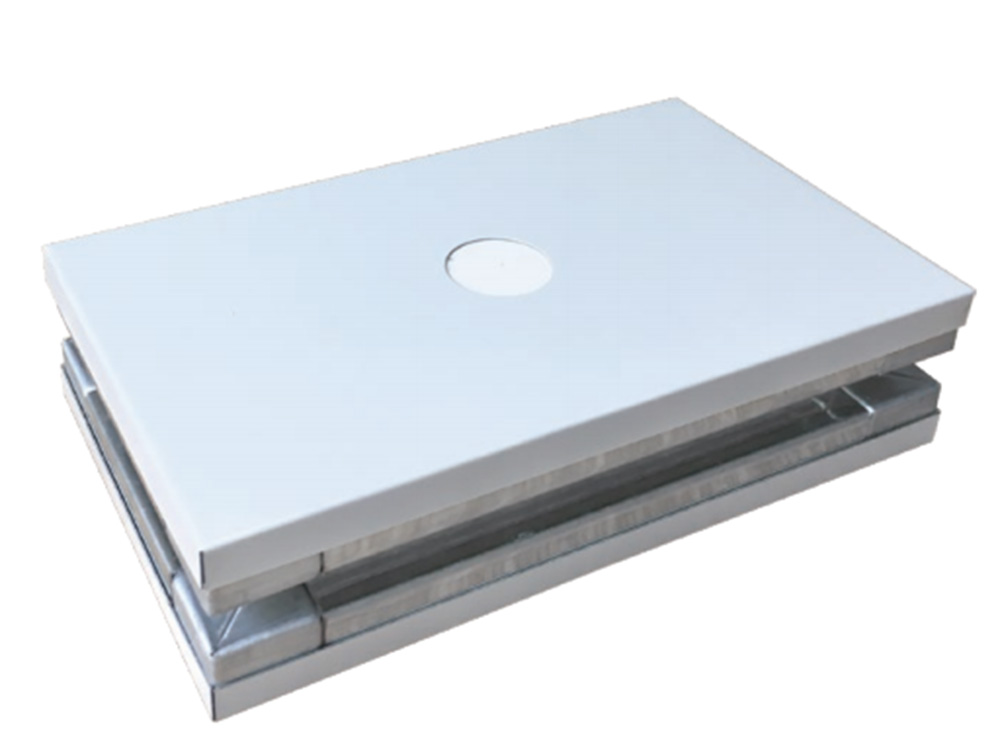

PU/EPS/PIR Cleanroom Panel

- Superior Thermal Insulation

- Lightweight & easy installation

- Energy-efficiency

Solves: Economic advantages than rockwool and magnesium systems

Lightweight Rigidity

Lightweight Rigidity

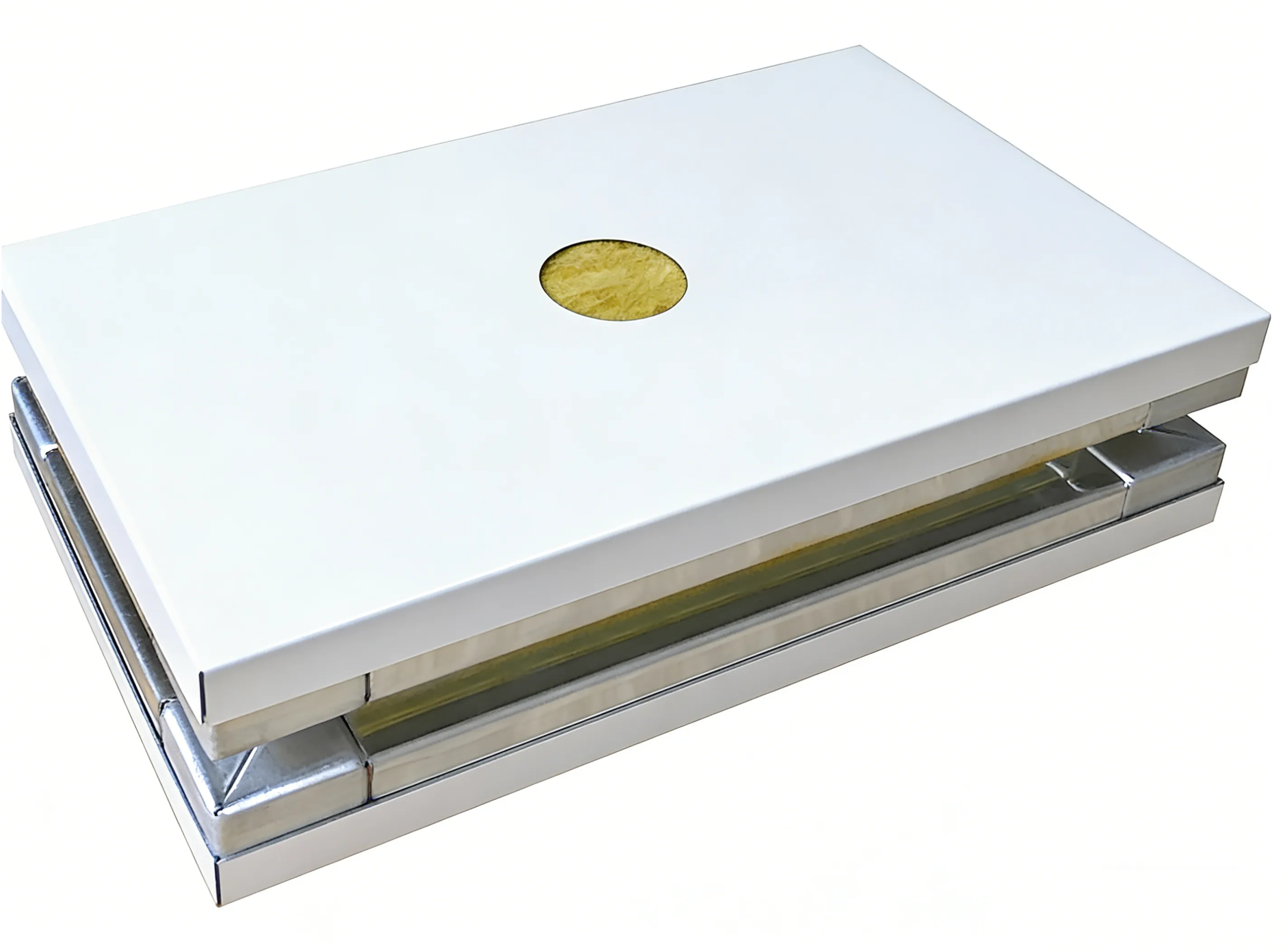

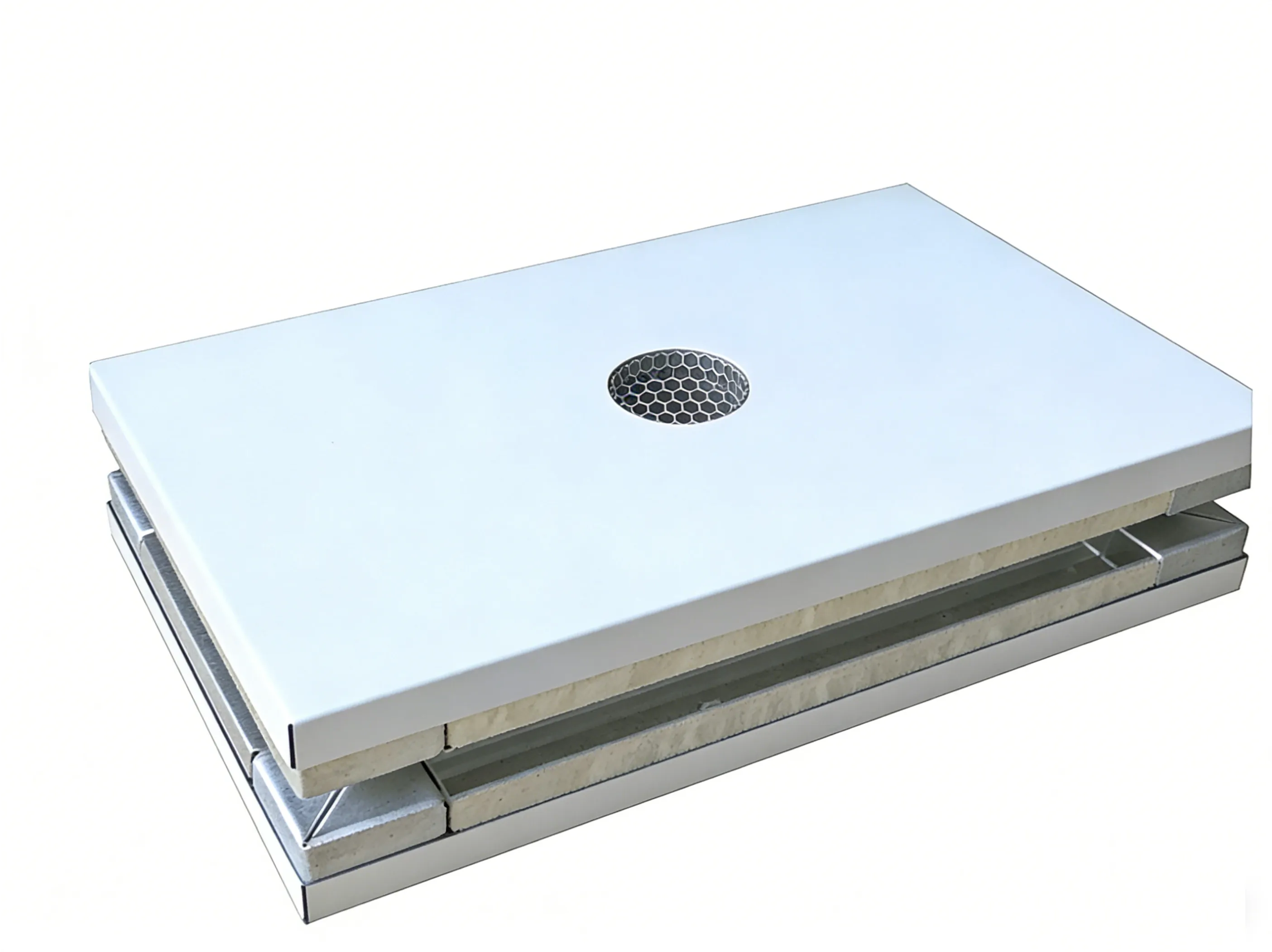

Aluminum/Paper Honeycomb Panel

- Lightweight core & Modularity

- Smooth surface

- Low particle accumulation

Solves: Structural load limits and fast installation

Hygiene & Durability

Hygiene & Durability

HPL/Stainless-steel Panel

- VHP Chemical resistance

- Certified Anti-scratch

- Long service life

Solves: Maintenance concerns and surface-lifecycle decision

Precision Manufacturing

Precision Manufacturing

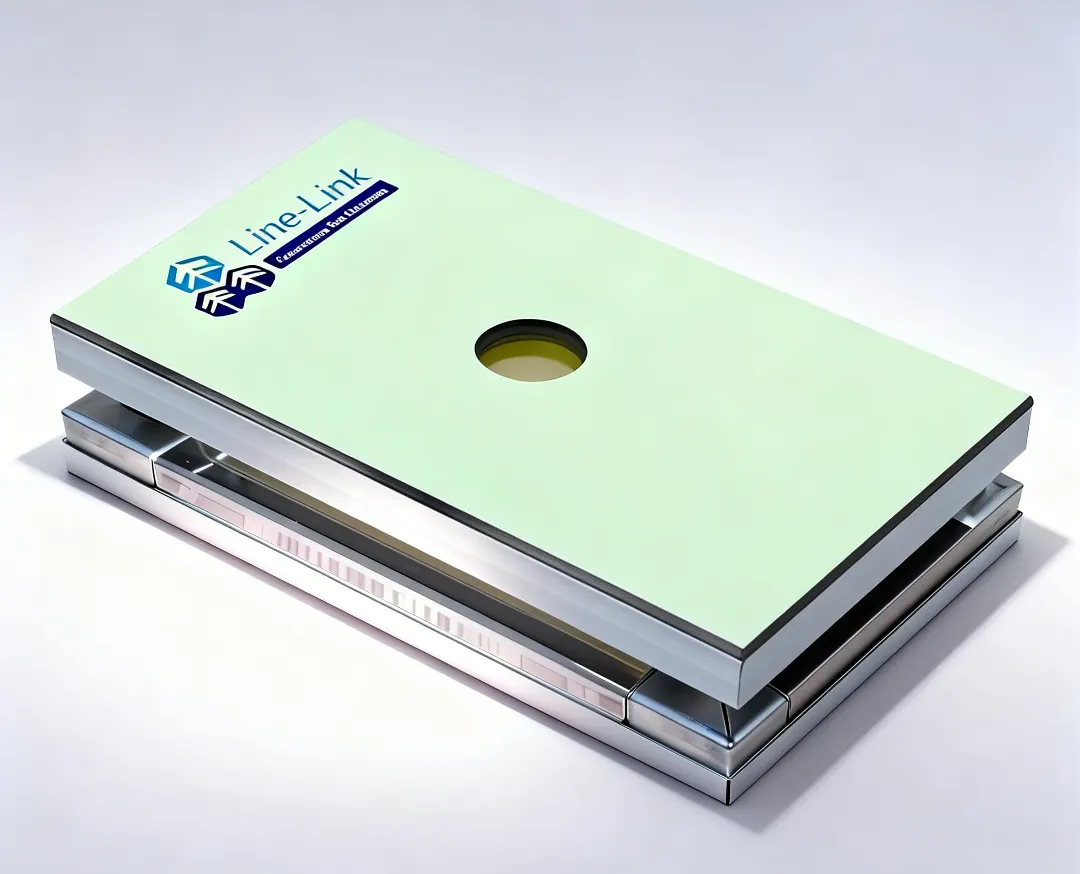

Machine-made Sandwich Panel

- ±0.1mm accuracy

- Continuous production

- Uniform density

Solves: Inconsistent quality

High Load & Airtight

High Load & Airtight

Ceiling Panels

- High load stability

- Airtight joint design

- Rapid reconfiguration

Solves: Structural sagging in large cleanrooms & High cost of future renovations

Products

faq

-

What types of cleanroom wall panels are available, and how do they differ in performance and application?

-

How do I choose between fire-rated panels and insulation-focused panels?

-

Are all panels suitable for different cleanroom iso classes?

-

Are hollow or honeycomb panels suitable for concealing utilities?

-

What is the difference between handmade and machine-made partition panels?