| Parameter | |

|---|---|

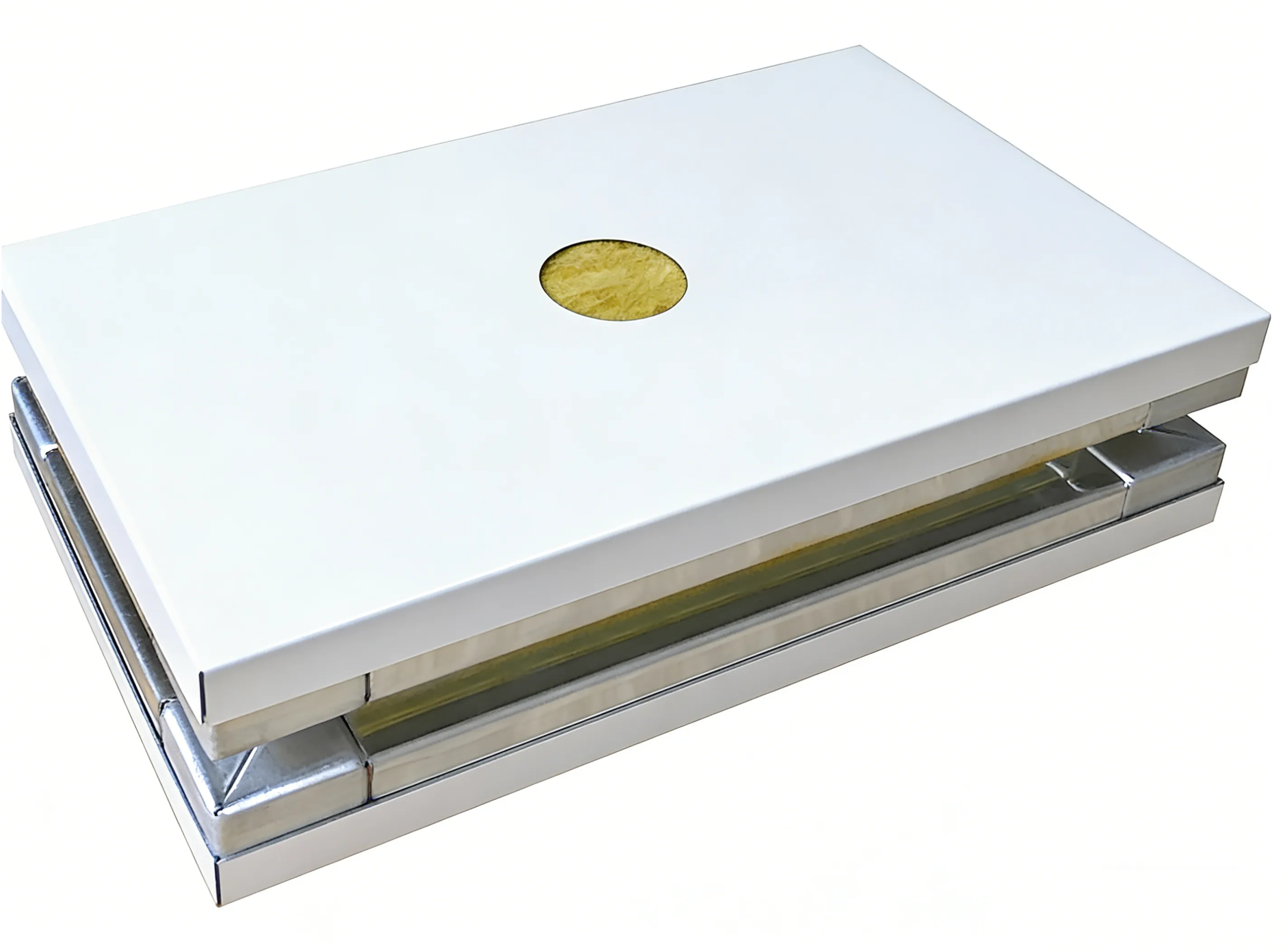

| Total Thickness | 50mm / 55mm / 75mm / 100mm |

| Standard Size (Width) | 980mm / 1160mm / 1180mm / 1200mm / Customizable |

| Diagonal Tolerance | ≤1mm |

| Max. Length | 10000mm |

| Coating Options | PE / PVDF / Antistatic / Stainless Steel / HDP / PVC |

| Sheet Thickness | 0.5mm / 0.6mm / 0.7mm / 0.8mm / 1.0mm |

| Insulation Material | Rockwool / Available for 2 Layers of MGO |

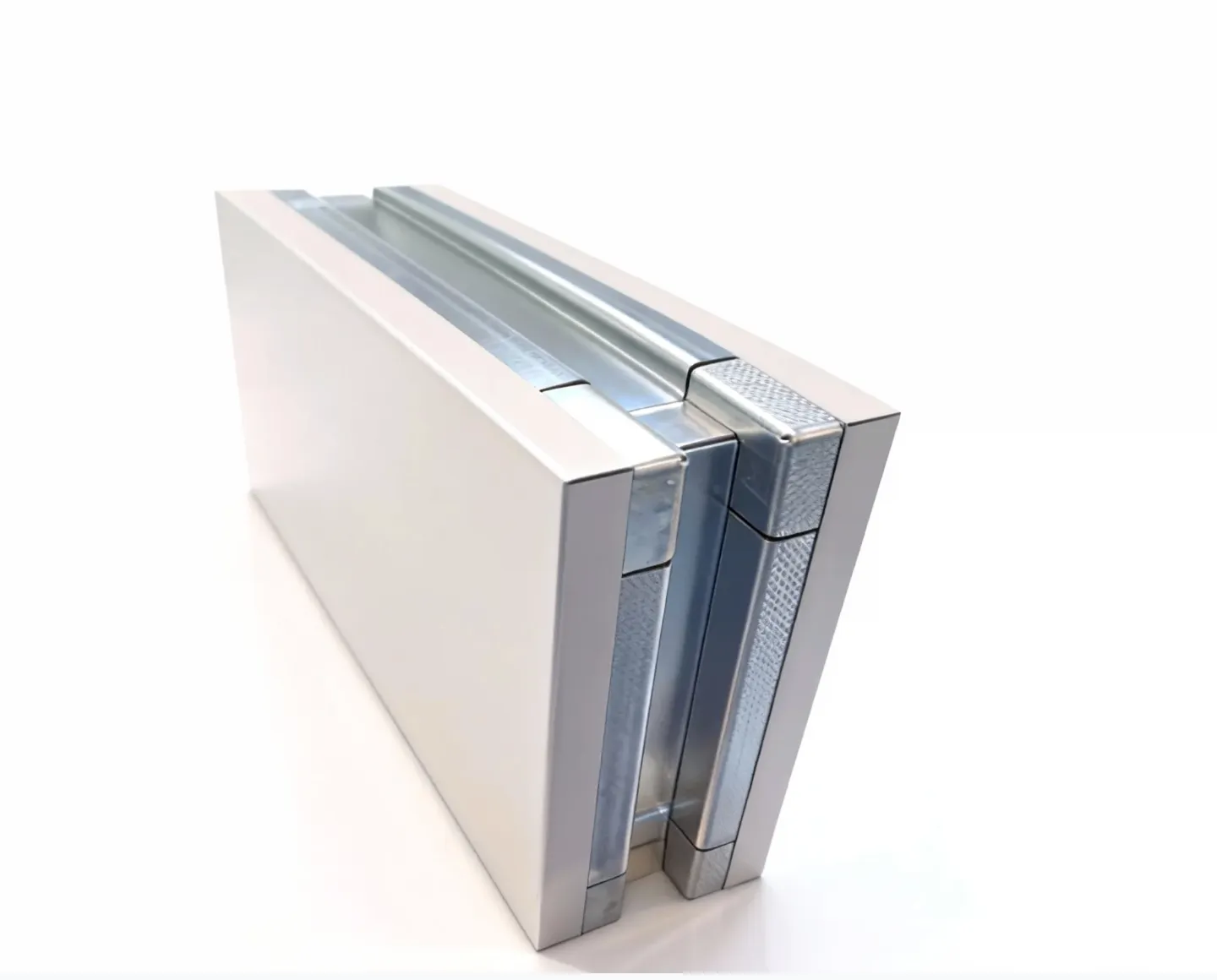

| Panel Frame | 0.8mm Galvanized Steel |

| Corner Connection | 1.0mm Galvanized Steel |

| Protection Film | 0.06mm (Customizable if T>0.06mm) |

| Flexural Capacity | 0.9KN/M² |

| Bonding Performance | 0.15mpa |

| Peeling Performance | ≥ 85% — ≤ 98% |

| Heat-transfer Coefficient | 0.73W/M²·k |

| Fire Resistance | 120 minutes |

| Connection Type | Aluminum Joint Type / Continuous Type |

Superior Fire Safety

A1 non-combustible core with 120-minute fire resistance rating provides maximum protection for critical cleanroom environments.

Thermal Efficiency

0.73 W/m²·K lower heat-transfer maintains stable room conditions, lowers HVAC load, and supports GMP temperature deviation control

ESD Protection

Anti-static coating (10⁶–10⁸ Ω/sq) protects sensitive electronics and processes in ESD-critical environments.

Fast Installation

Continuous tongue-and-groove joint design reduces installation time by 25% and sealant joints by 30%.

Compliance Readiness

Full certification package accelerates GMP validation, inspection sign-off, and project handover with fewer documentation gaps

Modular Flexibility

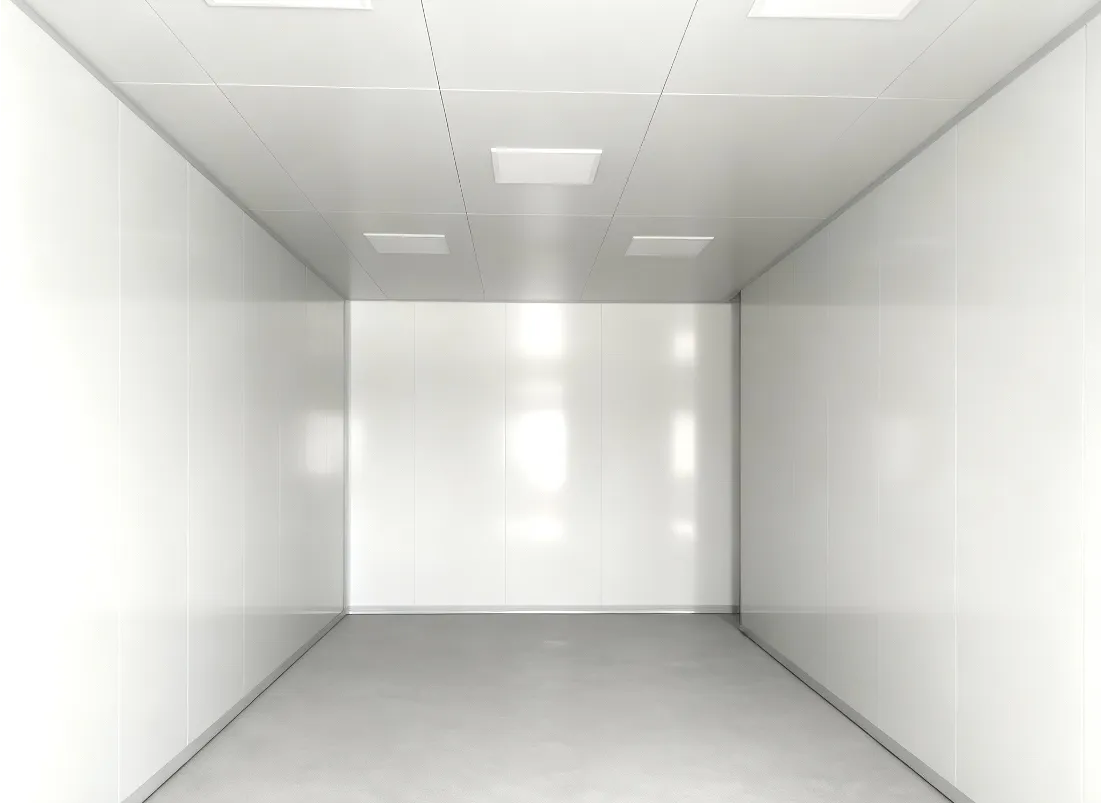

Thin profile (50/75mm) supports mounting of HVAC, piping, and FFUs without additional framing.

A turnkey wall solution that integrates fire safety, chemical resistance, structural strength, thermal efficiency, and rapid installation, letting engineers and technicians meet critical cleanroom standards with confidence and reduced risk.